FLEXOGRAPHIC PRINTING HOUSES

TYPES OF ROLLERS

- printing rollers

- varnishing rollers

- application rollers

- laminating rollers

- anilox rollers

- anilox sleeves

- rubber sleeves

- printing sleeves

ROLLERS AND SLEEVS FOR PRINTING AND LAMINATION

We refurbish and produce new rubber rollers and sleeves for printing with water-based, solvent-based and UV inks.

RUBBER CHARACTERISTICS

Rubber compounds for printing rollers and rubber sleeves as well as printing rollers for flexographic printing are characterized by high resistance to solvents (e.g. ethyl alcohol, ethyl acetate).

LASER ENGRAVED AND SMOOTH SLEEVES

Rubber sleeves are offered in a smooth option – for full covering printing or in a laser-engraved option – for endless printing.

SLEEVES WITH STEEL NOTCHES

Rubber sleeves for printing can be made with notches made in a steel ring – in this option, notches have an incomparably longer service life than a notches made in rubber. An additional advantage is the lack of risk of notch falling out and damaging machine components.

If the technical condition of the base is good, sleeves can be refurbished many times by replacing rubber with a new one.

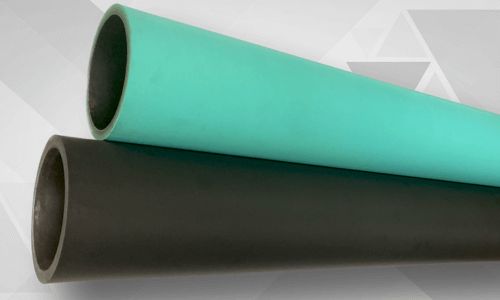

ROLLERS AND SLEEVES FOR LAMINATING MACHINES

A separate group are laminating rollers and laminating sleeves used in laminating machines, which are often used in flexible packaging printing houses – we offer both – refurbishment and new rollers and sleeves for this type of machines.

For sleeves and laminating rollers, our offer includes several rubber mixtures in various hardnesses and rubber colors, depending on the customer’s preferences (the color of the rubber has no influence on the roller’s operation)

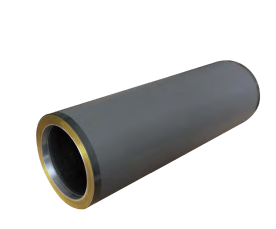

ANILOX ROLLERS AND SLEEVES

Our offer also includes anilox rolls and anilox sleeves. Anilox application rollers are used to apply ink, varnish and glue, we offer them in 2 options:

- ceramic anilox

- chrome anilox

We offer anilox rollers and anilox sleeves for machines printing on film, paper and cardboard. Our offer includes anilox refurbishment as well as new anilox rollers and sleeves.

Depending on industry, we offer anilox rollers and sleeves for machines such as: Windmöller & Hölscher KG, Comexi, Uteco, Bobst, Goepfert, Soma, Nipleter, OMET, Mark Andy and others.

Anilox roller is responsible for applying a precisely defined amount of ink, glue or varnish to substrate. Therefore, the quality of the anilox roller has a huge impact on quality of printing and application of varnish and glue. We adjust capacity of anilox rollers to amount of medium we want to apply to material.

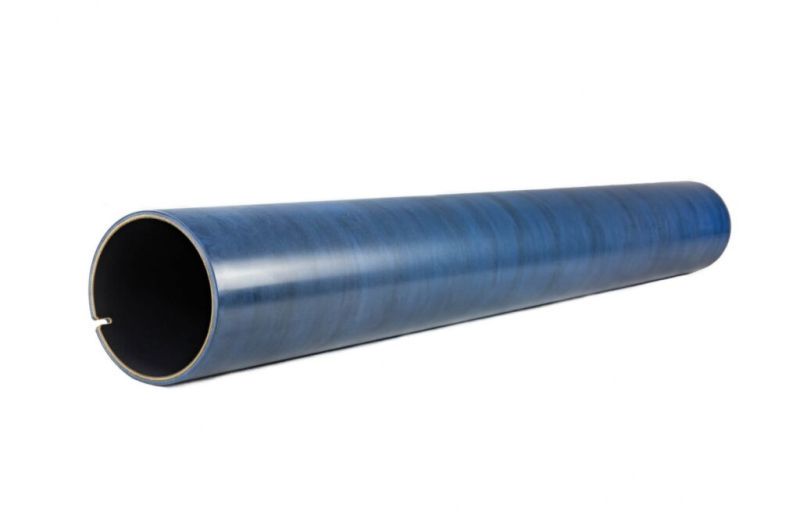

PRINTING SLEEVES

We offer printing sleeves made of composite intended for both water-based and solvent-based printing. For flexible packaging printing houses using solvent-based inks, we offer antistatic printing sleeves with properties that allow for discharge of charges.

The offered printing sleeves have the following properties:

- Reduces resistance during production processes

- Discharges static charges generated during printing

- Surface conductivity value <10^5 Ohm

- Cross conductivity value <10^6 Ohm

- Color – steel blue, green or pink.