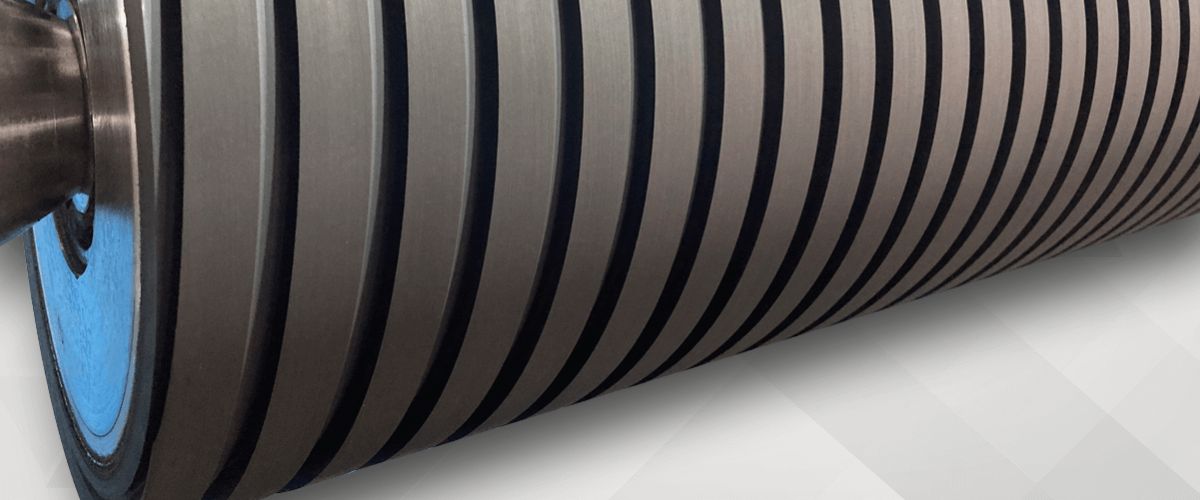

Refurbishment of rubber rollers

Rubberizing the rollers

Rubberizing is a process when old, used rubber is removed from roller and new rubber compound is applied in hot vulcanization process. Our specialty is refurbishment of rubber rollers and sleeves for various industries, using rubber compounds from proven European producers.

Cylindrical

Spheric

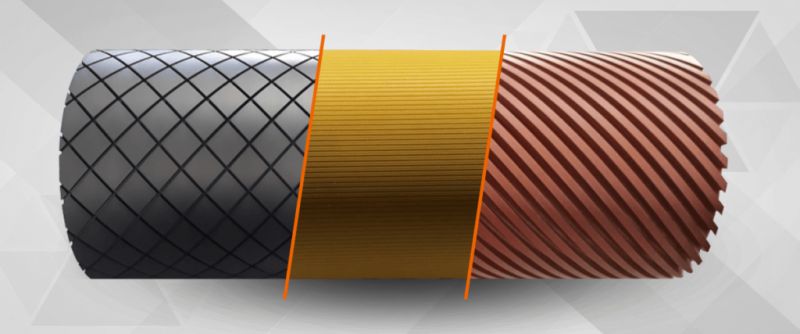

TYPES OF GRINDING

Concave

Cone

ELASTOMER SELECTION

Refurbishment of rollers by applying rubber, silicone or polyurethane is closely related to operating conditions of roller in machine. Based on the information provided by customer regarding the function and operating environment of roller, we select kind of coating.

TYPES OF RUBBER COMPOUNDS USED

To refurbish rollers, we use proven rubber cpmpounds from suppliers from Germany and England: EPDM, NBR, NR XNBR, HNBR, SBR, HYPALON and others available on special order.

Rubber hardness range: from 23 ShA to 98 ShA

Ethylene-propylene-diene rubber

Advantages:

- Operating temperature range in air: -50°C / +130°C

- Hardness 20 Shore A – 95 Shore A

- Excellent resistance to ozone, aging and weather conditions

- Very good resistance to hot water, steam, acids, alkaline solutions and water- and glycol-based hydraulic fluids

Areas of application:

- rollers and sleeves for applying varnish

- rollers and sleeves for applying glue

- rollers and sleeves for printing

- rollers for processors

- pressure rollers

- laminating machines

- other rollers where chemical and temperature resistance up to 130°C is required.

Nitrile rubber

Advantages:

- Operating temperature range in air: -30°C / +110°C

- Hardness 20 Shore A – 75 Shore D

- Very good abrasion resistance

- High durability (depending on the filler), similar to natural rubber

- Good resistance to oils and fuels

Areas of application:

- pressure rollers

- transport rollers

- glue rollers

- printing rollers (water-based inks)

- embossing rollers

- other rollers where there are no aggressive chemicals and operating temperature does not exceed 110°C

Natural rubber

Advantages:

- Operating temperature range in air: -55°C / +70°C

- Hardness 25 Shore A – 70 Shore D

- High flexibility/good resilience High strength, resistance to pressure and friction

- Good resistance to water, alcohols, glycols, dilute weak acids and alkali solutions

Areas of application:

- pressure rollers

- transport rollers

- glue rollers (water adhesives)

- printing rollers (water-based paints)

- ink rollers (water-based varnishes)

- embossing rollers other rollers where there are no aggressive chemicals and the operating temperature does not exceed 70°

Chlorosulfonated polyethylene

Advantages:

- Operating temperature range in air: -30°C / +150°C

- Hardness 45 Shore A – 95 Shore

- Very good resistance to ozone, aging and weather conditions

- Good resistance to oxidizing chemicals, organic and inorganic acids and alkalis

- Good heat resistance

- Good resistance to abrasion and pressure

Areas of application:

- pressure rollers

- application rollers

- guide rollers

- glue rollers

- paint rollers

- ink rollers

Hydrogenated nitrile-butadiene rubber

Advantages:

- Operating temperature range in air: -30°C / +150°C

- Hardness 50 Shore – 95 Shore A

- Resistance to mineral oils, fuels and oxidizing media

- Very good resistance to ozone, aging and weather conditions (especially fully hydrated varieties)

- High tear resistance

- Very good abrasive properties

Areas of application:

Rollers subjected to dynamic and abrasive loads under the influence of heat and media, including rollers for steel and paper factories.

Silicon

Silicon Advantages:

- Operating temperature range in air: -50°C / +220°C

- Hardness 35 Shore A – 90 Shore A

- High resistance to ozone, aging and weather conditions

- Insulating properties

- Anti-adhesive properties

- High heat resistance

- Resistant to mineral oils (non-aromatic), dilute acids and alkali solutions, alcohols and ketones.

Area of application:

- corona rollers

- pressure rollers

- applying rollers (glue)

- other rollers where anti-adhesive or insulating properties are required or the operating temperature exceeds 150°C

PROPERTIES OF RUBBER COATINGS

- antistatic

- conductive

- insulating

- with a certificate of approval for contact with food

- high temperature resistant (silicone)

- resistant to aggressive chemicals

- hard-to-wear with improved mechanical properties

We make new steel rollers, which we can be refurbished by rubber, silicone and polyurethane.

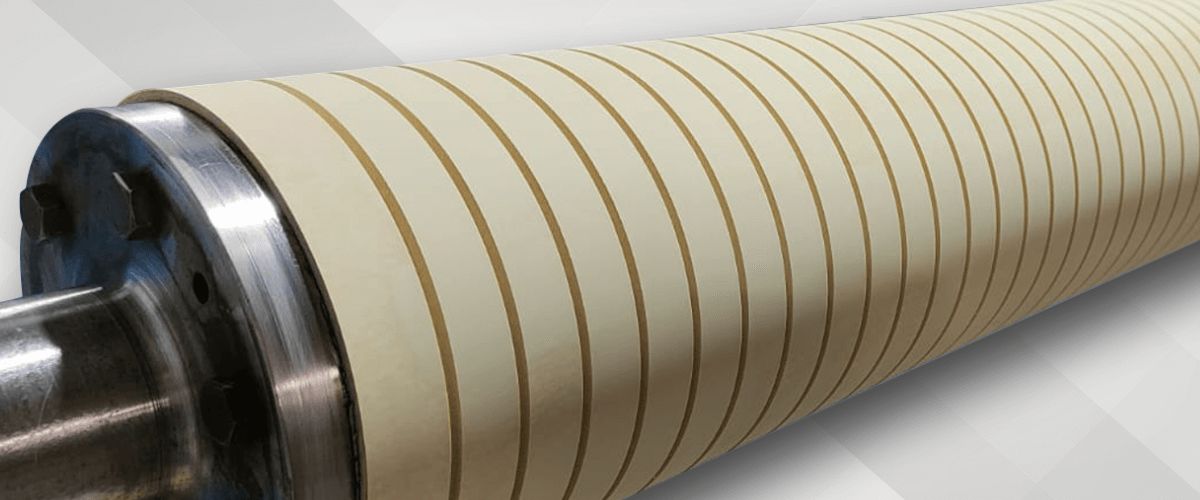

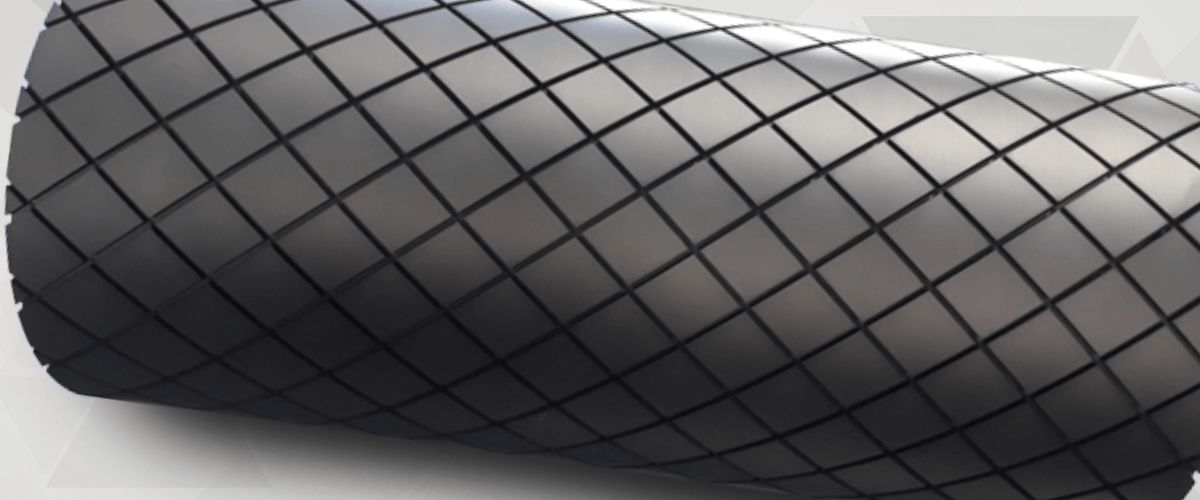

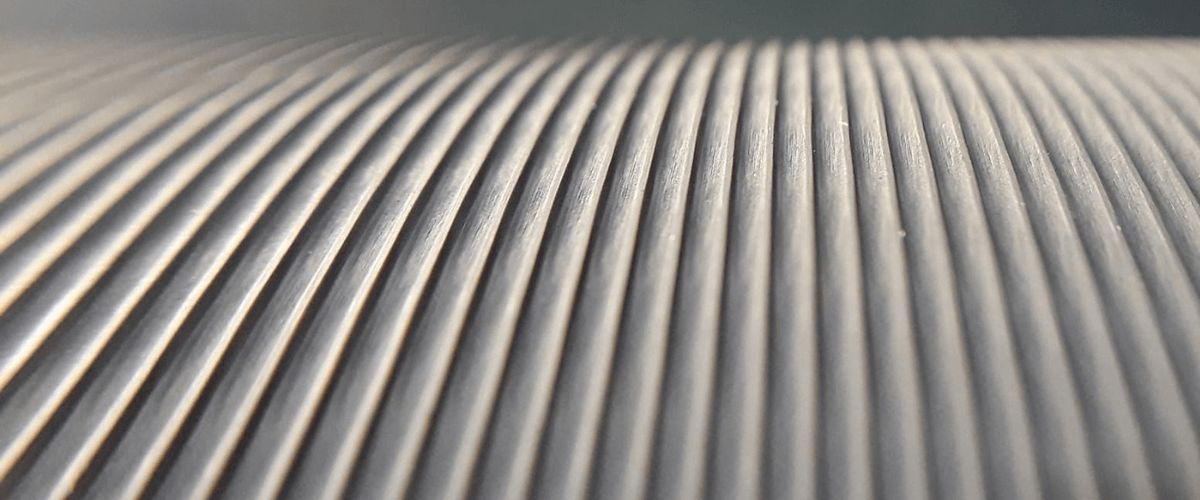

GRINDING

OF RUBBER

ROLLERS

If the minimum diameter of rubber roller or rubber sleeve has not been reached, we grind rubber until any irregularities or defects disappear. The grinding process allows us to shorten machine downtime to a minimum. After prior arrangement of delivery date, we can grind rollers immediately after delivery to our company.

DYNAMIC

BALANCING

OF ROLLERS

At the customer’s request, we offer dynamic balancing of rollers. Dynamic balancing is performed on Schenck’s machines by adding or removing material, depending on structure of roller and degree of underweight.

Laser engraving of rollers and rubber sleeves

We offer laser engraving of rubber rollers and sleeves used in flexo printing houses for film, paper and sheet metal packaging.

Recipients of our services

The recipients of our services are printing houses, paper mills, and companies from the packaging, wood and textile industries. We work with large corporations with branches all over the world as well as small companies from the local market

PRODUCTION POSSIBILITIES

Rubber rollers are ground on CNC grinders. The maximum dimensions of rollers that we can rubberize and grind are:

- Maximum diameter D 600 mm

- Maximum length L= 4900 mm (working length), L= 5500 mm (total length with shafts)

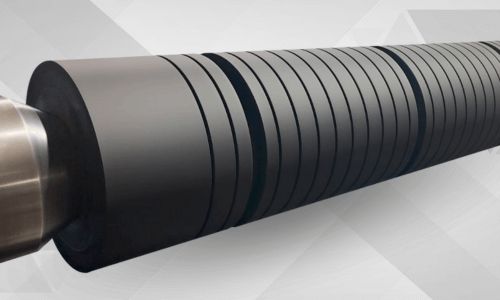

GROOVING OF RUBBER ROLLERS