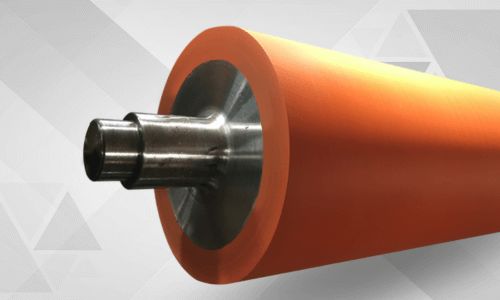

REFURBISHMENT OF SILICONE ROLLERS

SILICONE COATINGS

Silicone coating is a process of applying silicone compound to rollers and wheels.

Silicone coatings are usually used on rollers operating at temperatures above 150-160 °C, on corona rollers or when anti-adhesive coating is required.

Silicone is resistant to constant temperatures up to 220°C, while temporary resistance is up to 310°C.

We use silicone coating, among others: on pressure rollers in laminating machines and laminators, on crown rollers or rollers applying e.g. adhesives. Silicone rollers can be regenerated by us and we can also offer the production of a new roller based on a drawing or a reference roller.

We offer silicone coating on small rollers and wheels as well as large cylinders up to 4900 mm in length and a maximum diameter of 600 mm.

Hardness range: 30-90 ShA