OFFSET PRINTING HOUSES

Production and refurbishment of rollers for offset printing machines:

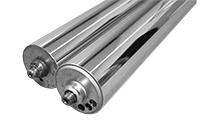

Production and refurbishment of chrome rollers

Refurbishment of oscillator rollers

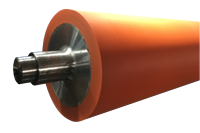

Refurbishment of rubber and silicone rollers

Refurbishment of folding machine rollers

Chemicals for printing houses

WE REFURBISH ROLLERS FOR MACHINES SUCH AS:

Sheet-fed and roll-fed offset machines

Oscillator / rilsan rollers – we use a special compound substitute for the Rilsan coating – it is a hard, hard-to-wear coating, polished to a high gloss.

REPLACEMENT FOR RILSAN COATING

Offered substitute for the Rilsan coating is a hard rubber, resistant to abrasion and type of inks used in conventional printing.

Chrome rollers – refurbishment of chrome rollers is performed by applying chrome using the galvanic method, followed by grinding of chrome and then polishing it. Chromium hardness 63 HrC, roughness of chrome coating Ra = 0.04 – 0.08 um. We also offer new chrome rollers.

Anilox rollers – anilox rollers with a ceramic coating are used as varnishing rollers. We offer refurbishment as well as new anilox rollers and sleeves for offset and flexographic machines.

Offset plate processor

Rubber rollers – we use rubber that is resistant to chemicals used in offset plate processors. Rubber hardnesses is 25-60 ShA.

Spiral and ring folding rollers

We offer refurbishment of rollers from folding machines with spiral and ring covering. We refurbish rollers with a polyurethane coating in hardnesses of 50 and 70 ShA.

We refurbish rings and spiral coatings of rollers in machines from popular manufacturers such as Heidelberg, GUK, Stahlfolder, MBO, Herzog & Heymann and Horizon

Laminating machines

We use rubber and silicone for pressure rollers – coatings used are resistant to pressure and high temperature:

– 140 °C rubber

– 220 °C silicone

Chrome rollers – refurbishment of chrome rollers is performed by galvanic chrome plating, followed by chrome grinding and then polishing. Before refurbishment, rollers are ground until the appropriate surface is obtained

Chrome hardness 63 HrC, chrome coating roughness Ra = 0.04 – 0.08 um