Embossing rollers

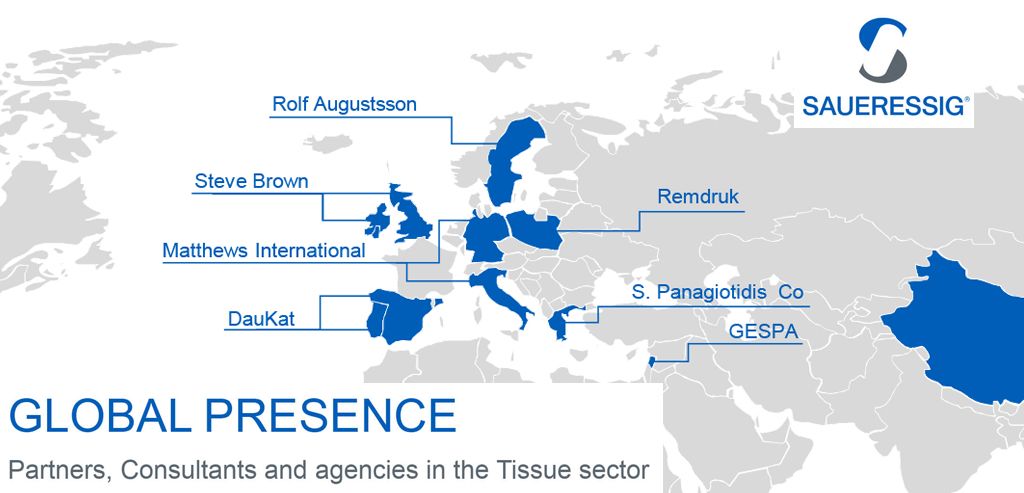

Together with SAUERESSIG SURFACES, Matthews International Corporation owns the subsidiaries Saueressig GmbH + Co.KG, UNGRICHTGMBH + CO.KG, WETZEL GmbH, Saueressig Design Studio GmbH and DORNBUSCH ENGRAVING GMBH under the umbrella brand Matthews International Corporation.

As the leading international supplier of rotogravure rollers and embossing cylinders, SAUERESSIG SURFACES offers excellent quality rollers as well as support and technical expertise.

We provide services to companies producing handkerchiefs and hygiene products, non-woven fabrics and floors, as well as the plastics processing industry. The brand also combines a wide range of competences in the field of surface design. These are used primarily in the field of decoration, as well as in the automotive, leather and wallpaper industries.

By combining five families, Matthews combines decades of experience from various space sectors into one new brand, and that’s what our corporate strength, tradition and reliability are all about.

Renovation / recovering of embossing rollers with a copper layer

Roller recovering stages:

- removing old engraving

- reconstruction of the original shaft diameter by special copper plating

- engraving a new desired design

chrome plating

Multiple use of steel bodies allows for:

- cost reduction

- short lead times

Chrome protects the surface from corrosion and abrasive wear.

Pattern design services for printing and embossing rollers

Pattern design services for printing and embossing rollers.

The creative implementation of your surface design is carried out by experienced designers and experts who will take care of all important technical details with particular care.

Before creating the technical data, the new design will be analyzed for potential problems and then optimized.

In order to offer you a clear picture, the estimated final result, we offer a 3D simulation that shows the finest details.

Roller testing machine

In our in-house pilot plant, we test the newly developed projects. Only after successful tests we produce a new pattern on your rollers.

Embossing rollers and sleeves

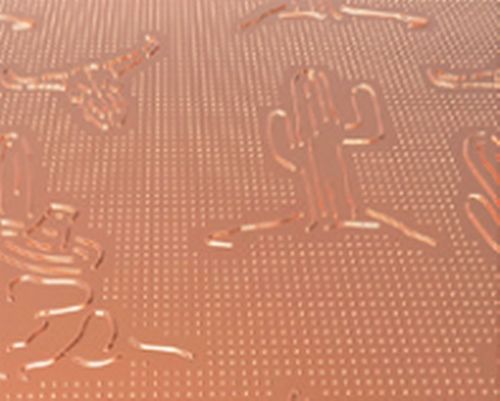

We manufacture new rollers and sleeves to order. The rollers are engraved with the latest laser, etching technology or with special engraving tools. The mentioned technologies allow us to accurately recreate even the smallest structures.

Rollers and sleeves embossing patterns

Roller properties:

- surface hardness up to 65 HRC

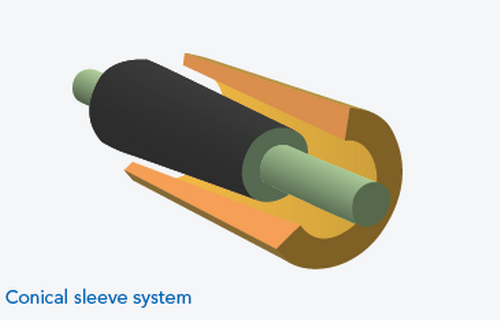

- innovative materials and technology of conical sleeves

- special coatings to protect against abrasion

Services:

- shaft installation / replacement services

- storing rolls, thanks to which short delivery times

Advantages of sleeves:

- repeated use of sleeves saves time and costs

- reduced vibrations

- long service life

- various embossing options

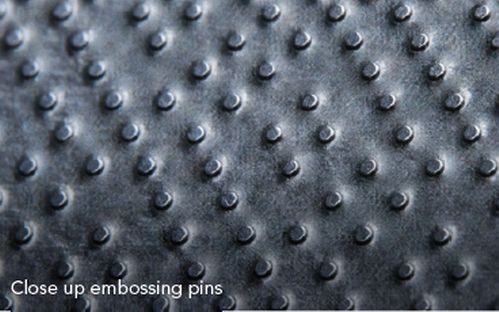

- optimized pin quality thanks to a new finishing process

- calculation of the area of ??embossed patterns

Thanks to close cooperation with our company, the client gains:

- improving the quality of extrusion and extending the life of the rollers

- active management of the supply chain through warehousing and delivery as requested by the customer on demand